Collet closer

Making a lever-actuated collet closer

I’ve got a 10” 1947 Montgomery Wards (Logan) metal lathe. Like many, I enjoy the convenience and precision of collets. A four-jaw chuck is much more tedious to align, and none of my scroll chucks provide as much precision.

Until recently, I regularly used three different collet systems: 3C, 5C, and ER-32.

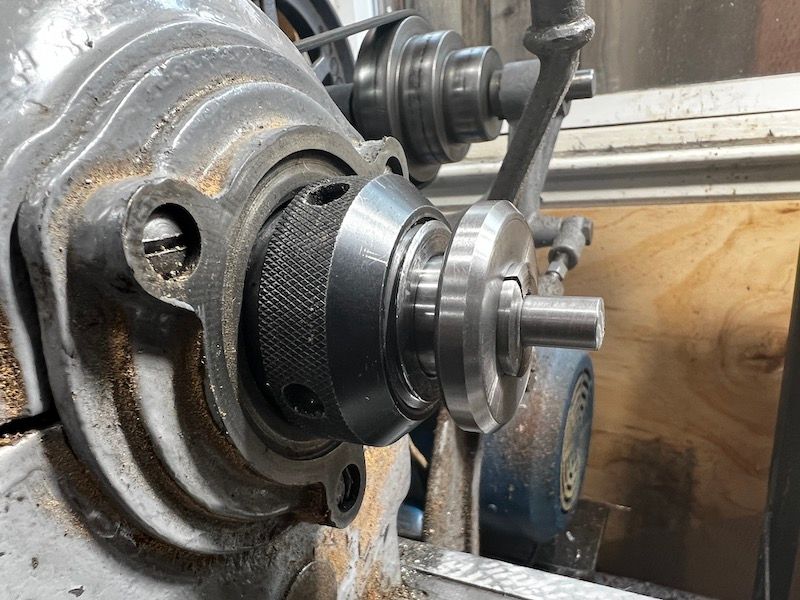

The lathe spindle has a 3MT morse-taper at the nose. For years I’ve used 3C collets with an adapter and drawbar. I’ve acquired a full set of 3C collets from 1/16” to 1/2” in 1/64” increments.

The main drawback of the 3C collets is the maximum diameter of 1/2”, but the drawbar is also a little slow and tedious to use.

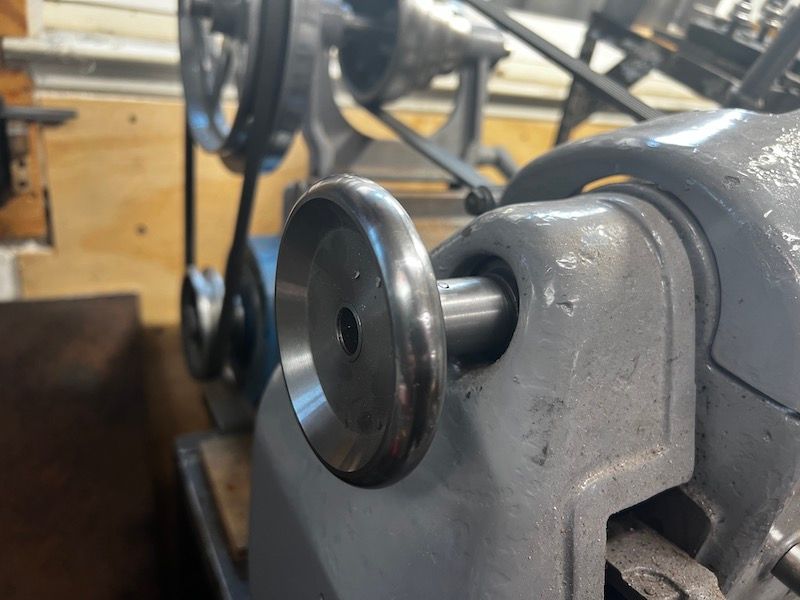

A few years ago I acquired a screw-on 5C collet chuck. This lets me hold onto larger diameter stock, and lets me use the same collets for milling (in collet blocks and indexers, etc.). Unfortunately, there are a couple disadvantages:

- The collet chuck sticks out too far for a relatively light-weight lathe. I get quite a bit of chatter with parting operations, etc.

- The scroll takes about a million turns of the chuck key to tighten down on parts.

I’ve also started using ER-32 collets with an adapter. This lets me hold onto “between” size stock, which is nice, but it also has a few problems:

- I’ve not made a drawbar, so I just bang the 3MT adapter into the end of the spindle and depend on friction to hold it in place (this works fine in practice).

- While not as bad as the 5C chuck, the work still sticks out far enough to cause problems with chatter.

A lever-actuator for 3MT collets

One problem in common with all of the above is that they either depend on screw-in drawbars or scroll chucks to tighten the collet. This is admittedly just a minor inconvenience for a hobbyist like myself, but I always wanted a lever-actuated collet closer like you find on a big-boy lathe for production work.

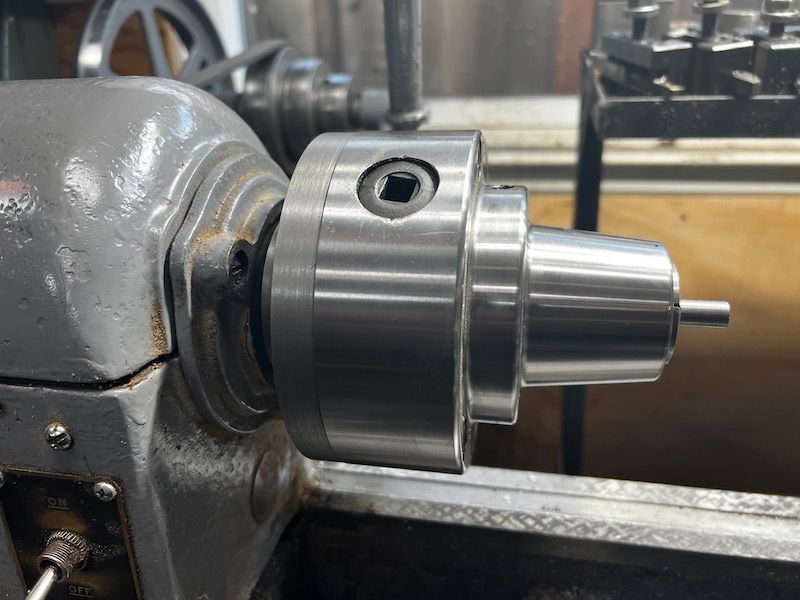

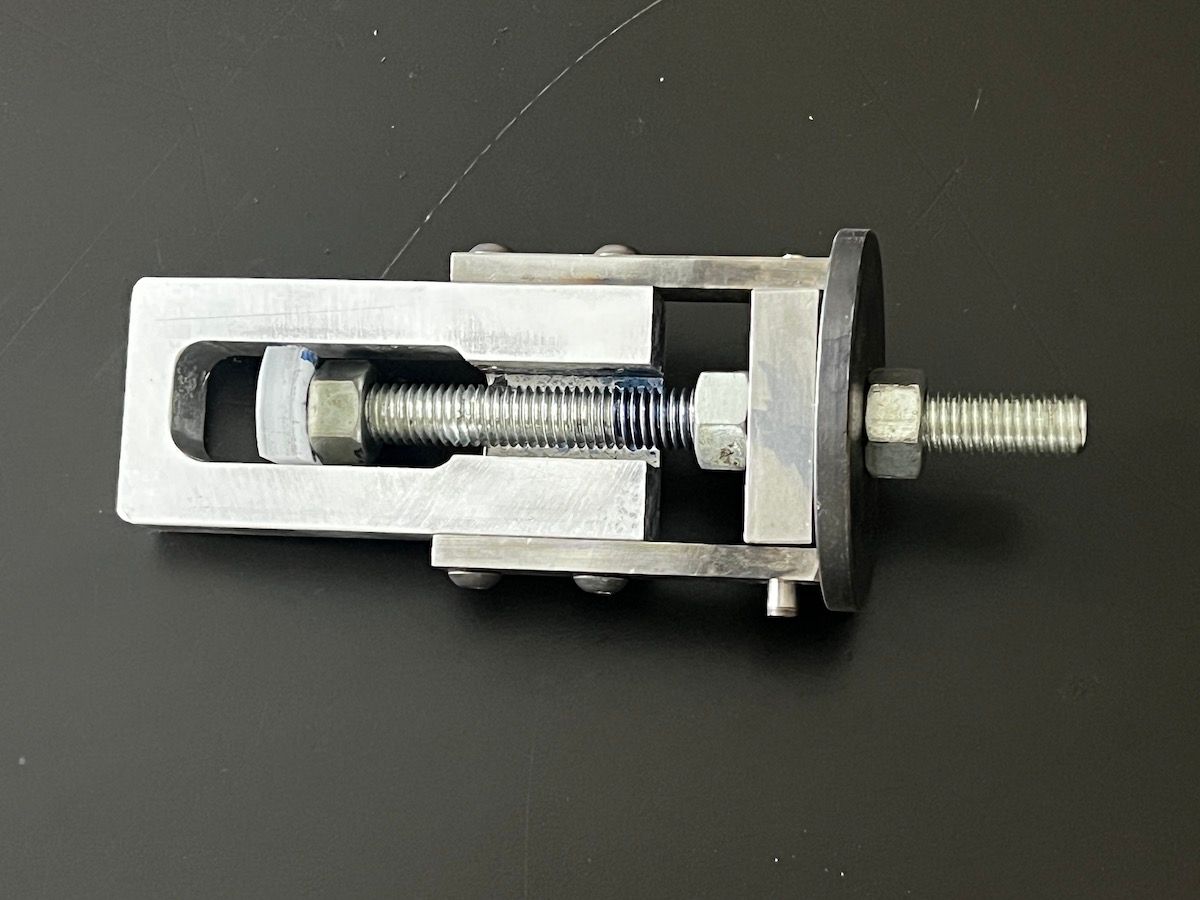

My friend Jim S. had an idea for a “ghetto” version of a lever-actuated drawbar:

The idea is to use a length of all thread as a drawbar, with a cam-actuated assembly that revolves with the spindle at the far left of the lathe. This isn’t quite as nice as a “real” lever-actuated collet closer where the lever doesn’t spin, but it’s a lot easier to make.

I just received some cheap 3MT collets that I’d ordered. I plan to experiment with this for a few days. If it works well, I’ll draw it up in CAD and send out to someplace like SendCutSend for a short run of parts. I figure anyone with a similar 10” or 11” Logan or South Bend lathe might also be interested in a kit to make one.

You obviously need to wait for the spindle to stop before acuating the cam, but it’s still more convenient than screwing down a drawbar for repetitive work.

Where the cam rubs should really be hardened. I’m thinking of using hardened washers to make the manufacturing as simple as possible.

The 3MT collets have a 3/8”-16TPI drawbar thread, so I’ll need to make an adapter that goes between the 1/2” all-thread and the collet. I also need to make some spacers that fits somewhat snuggly in the spindle to keep the all-thread centered.

Lastly, I think I’ll probably use this most with ID collets. But that will be another post.

I’ll post updates as I make progress.