Repairing a cupholder

Replacing a car cupholder part.

My wife came to me a few days ago asking if I could repair the cupholder in her car.

The cupholder is a two piece assembly. The top piece is spring loaded and hinges on two little nubs on the sides. Here’s a view of the assembly with the original parts:

The nub on one end was broken. Here’s a view of the original injection-molded part:

A normal person would have just drilled a hole in the end and inserted a little pin to act as a hinge.

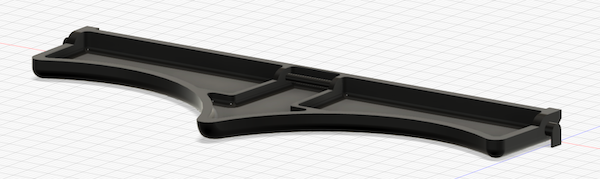

Instead, I designed a whole new part in fusion 360. That link should take you to a viewer for the 3D model, but here’s a static image:

Notes:

The nubs create “overhangs” where the 3D printer would need to print over empty air (causing droops and ugliness). To work around the problem I added some integral supports. After printing, I just broke off those supports with my fingers and cleaned it up a bit with a file.

The spring is held in place between two little nubs between the center ribs. Rather than dealing with supports, I just printed a complete cylinder that goes all the way from one rib to the other. After printing, I just took a pair of nippers and cut out most of the center portion so I could put the spring in place.

Here’s a short video of the final results: